Call us Now: +91 94433-94275, +91 94433-90259

MANUFACTURING GAS

TRADING GAS

GAS REGULATORS

Pure acetylene is a colourless gas with a pleasant odour; as prepared from calcium carbide it usually contains traces of phosphine that cause an unpleasant garliclike odour.

Acetylene can be decomposed to its elements with the liberation of heat. The decomposition may or may not give rise to explosions, depending on conditions. Pure acetylene under pressure in excess of about 15 pounds per square inch or in liquid or solid form explodes with extreme violence.

Mixtures of air and acetylene are explosive over a wide range, from about 2.5 percent air in acetylene to about 12.5 percent acetylene in air. When burned with the correct amount of air,acetylene gives a pure, white light, and for this reason it was at one time used for illumination in locations where electric power was not available, e.g., buoys, miners' lamps, and road signals.The combustion of acetylene produces a large amount of heat, and, in a properly designed orch, the oxyacetylene flame attains the highest flame temperature (about 6,000° F, or 3,300° C) of any known mixture of combustible gases.

The hydrogen atoms in acetylene can be replaced by metallic elements to form acetylides--e.g., acetylides of silver, copper, or sodium. The acetylides of silver, copper, mercury, and gold are detonated by heat, friction, or shock. In addition to its reactive hydrogen atom, the carbon-carbon triple bond can readily add halogens, halogen acids, hydrogen cyanide, alcohols, amines,

and amides. Acetylene can also add to itself or to aldehydes and ketones. Many of the reactions mentioned here are used for the commercial manufacture of various industrial and consumerproducts, such as acetaldehyde, the synthetic rubber neoprene, water-base paints, vinyl fabric and floor coverings, dry-cleaning solvents, and aerosol insecticide sprays. Acetylene isproduced by any of three methods: by reaction of water with calcium carbide, by passage of a hydrocarbon through an electric arc, or by partial combustion of methane with air or oxygen.

Liquid Oxygen contains 17.5% hydrogen peroxide H202.

Liquid oxygen also reffered to as LOX, is a versatile and efficient means of supplying oxygen to the hospital patient. The system usually consists of a bulk storage reservoir unit that remains in a permanent place in the home and a portable, refillable lightweight carrrying container. Both the reservoir and portable units are constructed similar to a thermos bottle consisting of an inner and outer container with a vacuum in between.

The bulk storage unit is normally filled with anywhere from 40 to 100 lb of liquid oxygen. However, the typical setup usually contains around 100 lb of liquid oxygen (equals 33,756 Liters of gaseous oxygen) and provides a low working pressure between 20 and 90 psig. The storage unit can be used to deliver oxygen directly to the patient or be used to refill a portable unit carried around by the patient.

The portable, refillable carrying container is filled from the storage unit when necessary. When full, the portable container weighs between 6 and 11 lbs and provides approximately 1,025 Liters of gas. The use of a permanent storage unit and a refillable portable unit allows the patient more freedom to move about.

Oxygen becomes a liquid at temperatures below its boiling point of -183�C and takes on a pale blue color weighing 1.14 times the weight of water. When the temperature of liquid oxygen is greater then -118.6�C, the liquid will return back into a gas regardless of the pressure exerted on it. This is known as the critical temperature. 1 Liter of liquid oxygen provides 860 Liters of gas.

The liquid oxygen is kept in insulated containers (called dewars). These keep the oxygen in liquid form at a temperature of -170 degrees Celius. The container consists of a lower portion where the oxygen is in a liquid state and a smaller upper portion where the liquid has evaporated creating a gas. When the unit is being used by the patient, a flow control valve is opened to deliver oxygen to the patient. This creates a pressure gradient between the gas-filled upper portion of the container (called the head pressure) and the atmospheric pressure. Liquid oxygen passes through a warming coil, is converted to a gas, and is made available for patient delivery. When the upper portion falls below a certain pressure, liquid oxygen is drawn up from the bottom of the container to provide a constant flow to the patient.

Since the cooled liquid oxygen is under pressure, the room temperature will cause some evaporation of the liquid into a gas creating more pressure in the container. This usually occurs when the container is not being used on a regular basis. When the pressure reaches a certain point a primary relief valve will open to vent to the outside. If the primary valve fails, a secondary relief valve will take over when the pressure reaches 10 psig above operating pressure. There is often a small venting of oxygen by the device as part of its normal operation.

Typical oxygen reservoirs contain approximately 40 Liters of liquid oxygen (depending on the model) that may last 8-10 days at 2-Liter/min. The controls on the portable liquid oxygen container enable the patient to select oxygen flow rates that can be used with a nasal cannula, transtracheal catheter, mask, or other oxygen delivery device. Oxygen flows are usually limited to 6 Liter/min however on most models.

- Comes in 30 and 40 pter capacity

- Consumes no electricity

- Attractive design

- Oxygen flow rate up to 15 lpm

- Supppes oxygen continuously for up to 11 days (at 2 lpm)

- Loud noises are made when the smaller units are filled from the larger ones

- The connection can become frozen if the filling is not done properly. All connections should be airtight

- There is evaporation loss from the cannisters when they are not in use

- Tank needs to be refilled regularly by a service technician

- Odourless and colourless

- Blue in liquid form

- Boiling point -183°C

- Reacts chemically with many substances

- Vigorously supports combustion

- Materials not normally considered flammable can be ignited in an oxygen rich atmosphere

At ambient temperature oxygen supports life and gives rise to applications associated with breathing for humans, animals and micro-organisms. At elevated temperatures, oxygen vigorously supports the combustion of many substances leading to many applications in the production and fabrication of metals. Oxygen can also be used as a chemical reactant for catalytic and non-catalytic oxidation reactions mainly in the hydrocarbon and chemical processing industries.

Chemicals :Many oxidation reactions use pure oxygen rather than air to benefit from higher reaction rates, higher yields, easier product separation and , reduced capital cost of new plants and reduced air emissions.

Food : Oxygen can be used in fermentation to maintain an aerobic state. Also used in some cases for modified atmosphere packaging (MAP) of foodstuffs.

Fish farms : Higher levels of dissolved oxygen, resulting from the use of oxygen instead of air,allow more fish to be grown and remain healthy in a given volume of water.

Lasers : Oxygen is used as an assist gas for the cutting of mild steel and stainless steel.

Medical : Breathing oxygen instead of air allows greater oxygenation of the blood stream insituations of impaired breathing action and lung function.

Steelmaking and combustion processes : Oxygen is used to replace or supplement air in burners in many industries to obtain increased temperatures to increase throughput and improve energy efficiency. Typical industries include steel, non-ferrous, glass amongst many others

Water treatment : Oxygen can be used in place of air in the activated sludge process to maintain ahigher population of micro-organisms. Using oxygen injected through a side streaminstead of using a mechanical aerator eliminates surface agitation, reducing odour.

Liquid Nitrogen is nitrogen that is cold enough to exist in liquid form. It is used for many cooling and cryogenic applications. Here are some liquid nitrogen facts and information about handling liquid nitrogen safely.

Liquid nitrogen is the liquefied form of the element nitrogen that is commercially produced by fractional distillation of liquid air. Sometimes liquid nitrogen is denoted as LN2, LN, or LIN. Liquid nitrogen has the UN number 1977. At normal pressure, liquid nitrogen boils at 77 K (−195.8°C or −320.4°F). The liquid to gas expansion ratio of nitrogen is 1:694, which means liquid nitrogen boils to fill a volume with nitrogen gas very quickly.Nitrogen is non-toxic, odorless, and colorless. It is relatively inert. It is not flammable. Nitrogen gas is slightly lighter than air once it reaches room temperature. It is slightly soluble in water. Full line of products and services to streamline your medical gas-supply operation and reduce the stress of gas-supply management.

Liquid nitrogen is cold enough to cause severe frostbite upon contact with living tissue. Wear proper safety gear when handling liquid nitrogen to prevent contact or inhalation of extremely cold vapor. Make sure exposed skin surfaces are covered and preferably insulated.

TBecause it boils so rapidly, the phase transition from liquid to gas can generate a lot of pressure very quickly. Do not enclose liquid nitrogen in a sealed container, as this may result in bursting or an explosion.

Adding a lot of nitrogen to the air reduces the relative amount of oxygen. This can result in an asphyxiation risk. Cold nitrogen gas is heavier than air, so the risk is greatest near the ground. Use liquid nitrogen in a well-ventilated area.

Liquid nitrogen containers may accumulate oxygen which is condensed from the air. As the nitrogen evaporates, there is a risk of violent oxidation of organic matter.

- Nitrogen 99.999%

- Oxygen < 5vpm

- Moisture < 2vpm

- Argon is included in the nitrogen

- Refrigerated liquefied gas

- Boiling point -196°C

- Gas/vapour heavier than air

- Odourless, colourless and non toxic

- Chemically inert at ambient temperatures

- Freezing and transport of food products

- Cryopreservation of biological samples

- Coolant for superconductors, vacuum pumps, and other materials and equipment

- Cryotherapy to remove skin abnormalities

- Shielding materials from oxygen exposure

- Cooling materials for easier machining or fracturing

In its liquid form nitrogen is used as a cryogen for many applications where very low temperatures or rapid temperature reduction is required. The inert property of gaseous nitrogen enables it to be used for applications where a substance needs to be protected from oxidation or combustion by atmospheric air, or from contamination by moisture.

Argon is a chemical element with symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third most common gas in the Earth's atmosphere, at 0.93% (9,300 ppm), making it approximately 23.8 times as abundant as next most common atmospheric gas, carbon dioxide (390 ppm), and more than 500 times as abundant as the next most common noble gas, neon (18 ppm). Nearly all of this argon is radiogenic argon-40 derived from the decay of potassium-40 in the Earth's crust.

Argon is colorless, odorless and tasteless. It is know as one of the "Nobel" gases since it does not react reality with other materials and forms no known chemical compounds. It is nonflammable, will not support combustion and is not life-supporting. The gas is heavier than air and is only slightly soluble in water. When liquid argon is vaporized and then heated it consumes a large amount of heat, making it an ideal coolant.

Argon is present in the atmosphere at a concentration of ~1%. Argon is recovered from air in an Air Separation Unit (ASU) where it is drawn off as a cryogenic liquid at about -308°F. Argon can then be distributed as a cryogenic liquid or as a gas in cylinders.

Oxygen, nitrogen and argon are recovered from air using a cryogenic method developed by Carl von Linde more than 100 years ago. Particulates are removed from the incoming air, which is then repeatedly compressed and cooled. Water, hydrocarbons and carbon dioxide are then removed. With further processing, the air eventually becomes a liquid and the individual gases are separated by distillation. These plants are called air separation units, or Air Separation Units (ASU). Many of the world's ASUs have been built by Linde's engineering division.

- Argon 99.999%

- Oxygen < 2vpm

- Moisture < 1vpm

- Nitrogen < 6vpm

- Refrigerated liquid gas

- Boiling point -186°C

- Non-flammable

- Heavier than air

- Inert at most temperatures and pressures

- Colourless and odourless

- Constitutes 0.93% of atmospheric air

Oxygen is stored in two ways. Oxygen can be frozen and stored in containers that resemble thermos bottles. Oxygen can also be compressed and stored in cylinders under several thousands of pounds of pressure. This section discusses compressed oxygen. The next section discusses liquid oxygen.

Compressed oxygen for medical use is stored in silvery aluminum cylinders with dome-shaped tops of green. If you use compressed oxygen, your cylinder is probably one of those pictured in Figure 1.

Two sets of names are used to specify cylinder sizes. The older set identifies them alphabetically from A, the smallest, to E. the largest. You may be most familiar with the lightweight B cylinder or the E cylinder, which is usually pulled along in a cart.

Each of the newer set of names starts with the letter M to denote "medical," followed by a number, which specifies the amount of oxygen in cubic feet that can been compressed into the cylinder. For example, the B cylinder is also called the M-6 cylinder.

- Compressed Oxygen is typically supplied with a purity of 99.5% or better

- Colourless and odourless

- Does not burn but supports and accelerates combustion

- Non-toxic at atmospheric pressure

One of the most common uses of compressed oxygen is to provide supplemental oxygen for someone who has breathing problems. The type of oxygen cylinder used for this is usually a small lightweight portable tank, although a person who uses supplemental oxygen in her home may have a rather large tank so that she does not have to keep changing smaller tanks out as she runs out of oxygen rather quickly. Compressed oxygen is also used in welding.

Widely used with a fuel gas for cutting, welding, brazing and soldering. The use of oxygen gives higher flame temperatures than if air is used

In oxy-cutting, an oxy-fuel flame preheats the steel to its ignition temperature. A jet of gaseous oxygen flows onto the red-hot steel, generating more heat and melting the steel. The steel in contact with the oxygen jet is oxidised, creating metallic slag which is blown from the cut, allowing more steel to react with the oxygen

In plasma and laser-cutting steel, an arc or laser beam is used to heat the steel to its ignition temperature. Oxygen is then used in the same way as with oxygen-cutting to create an exothermic reaction and to blow away any metal oxide or slag

Thermal lancing oxygen is used in conjunction with the steel lance to create a high-temperature melting process capable of drilling or cutting through materials such as concrete, brick, stone and most metals

High-purity oxygen is used in the laboratories, process-control operations, metal analysis instruments and in semi-conductor production

Used as an assist gas in lasers for cutting mild steel

Vigorously supports combustion. Introducing oxygen to conventional air-fuel flames increases the temperature of the flame

Used as an ingredient in some shielding gas mixtures, due to its ability to help stabilise the arc and reduce surface tension

When cutting, a 1% reduction in purity increases oxygen consumption by 25% and reduces the cutting speed by a similar amount

Compressed Nitrogen is nitrogen in a liquid state at an extremely low temperature. It is produced industrially by fractional distillation of liquid air. Liquid nitrogen is a colorless clear liquid with density of 0.807 g/mL at its boiling point and a dielectric constant of 1.43. Liquid nitrogen is often referred to by the abbreviation, LN2 or "LIN" or "LN" and has the UN number 1977.

At atmospheric pressure, liquid nitrogen boils at −196 °C (77 K; −321 °F) and is a cryogenic fluid which can cause rapid freezing on contact with living tissue. When appropriately insulated from ambient heat, liquid nitrogen can be stored and transported, for example in vacuum flasks. Here, the very low temperature is held constant at 77 K by slow boiling of the liquid, resulting in the evolution of nitrogen gas. Depending on the size and design, the holding time of vacuum flasks ranges from a few hours to a few weeks.

Compressed Nitrogen can easily be converted to a solid by placing it in a vacuum chamber pumped by a rotary vacuum pump. Liquid nitrogen freezes at 63 K (−210 °C; −346 °F). Despite its reputation, liquid nitrogen's efficiency as a coolant is limited by the fact that it boils immediately on contact with a warmer object, enveloping the object in insulating nitrogen gas. This effect, known as the Leidenfrost effect, applies to any liquid in contact with an object significantly hotter than its boiling point. More rapid cooling may be obtained by plunging an object into a slush of liquid and solid nitrogen rather than liquid nitrogen alone.

Liquid nitrogen is produced commercially from the cryogenic distillation of liquified air. An air compressor is used to compress filtered air to high pressure; the high pressure gas is cooled back to ambient temperature, and allowed to expand to a low pressure. The expanding air cools greatly (the Joule–Thomson effect), and oxygen, nitrogen, and argon are separated by further stages of expansion and distillation. Liquid nitrogen may be produced for direct sale, or as a byproduct of manufacture of liquid oxygen used for industrial processes such as steelmaking. Liquid air plants producing on the order of tons per day of product started to be built in the 1930s but became very common after the Second World War; a large modern plant may produce 3000 tons/day of liquid air products.

- Odourless and colourless

- Non-toxic

- Does not support combustion

- An asphyxiant (does not support life)

- Non-reactive except at very high temperatures

- Does not react with oxygen at low temperatures

- Inert, dry and slightly soluble

- Available in 300-bar MCPs

Inert to nearly all substances at ambient temperatures and moderate conditions.

Nitrogen keeps laser-cut faces oxide-free due to the chemical inertness to react with the atmosphere.

At higher temperatures, nitrogen can react to form metal nitrides.

Nitrogen gas is only slightly soluble in a wide range of liquids and is therefore used to flush unwanted gases from solutions.

Reduces internal degradation of the rubber in tyres due to oxidisation.

As a cryogenic liquid, nitrogen can be used to thermally contract metals.

Used for blanketing and purging applications to displace or dilute all unwanted gas or vapour.

Widely used for reasons of safety and the prevention of product degradation in the chemicals and petroleum industry

Shielding or assist gas for plasma-cutting aluminium and stainless steel, and as an assist gas for laser-cutting stainless steel TIG-welding of tough-pitch copper.

Heat-treatment processes to protect some of the most reactive metals.

In electrochemical analysis, can be bubbled through to displace any oxygen.

Pressure-transfer, where the movement of liquids or slurries from one piece of process plant to another is effected using gas pressure.

Tyre inflation: helps to extend tyre life and prevent tyre bursts.

Pressurising accumulators for batch-testing applications.

Can be used for shrink-fitting: the intense cold of liquid nitrogen (-196°C), reduces the physical dimensions of a component placed in the liquid. Once cooled, the component is connected to a mating component before swelling to its original size as it reaches room temperature, thereby securing itself in place.

Oxygen (O2) is an active, life-sustaining component of the atmosphere; making up 20.94% by volume or 23% by weight of the air we breathe. It is colorless, odorless and tasteless.

Oxygen is the most widely occurring element on Earth. Because it forms compounds with virtually all chemical elements except the noble gases, most terrestrial oxygen is bound with other elements in compounds such as silicates, oxides, and water. Oxygen is also dissolved in rivers, lakes, and oceans. Molecular oxygen occurs almost entirely in the atmosphere.

Oxygen is highly oxidizing (a general chemical term applying to any substance, like oxygen, that accepts electrons from another substance during reaction). Oxygen reacts vigorously with combustible materials, especially in its pure state, releasing heat in the reaction process. Many reactions require the presence of water or are accelerated by a catalyst.

Ozone (O3) is an allotropic form of oxygen that is more reactive than ordinary oxygen. Ozone is formed in nature by electrical discharges or by irradiation with ultraviolet light. Commercial ozone generators mimic these natural process to make large amounts for industrial and environmental treatment processes or add a small amount of ozone to breathing air for its invigorating effect and "fresh air" scent.

Oxygen has a low boiling/ condensing point: -297.3°F (-183°C). The gas is approximately 1.1 times heavier than air and is slightly soluble in water and alcohol. Below its boiling point, oxygen is a pale blue liquid slightly heavier than water. Oxygen is the second-largest volume industrial gas. Aside from its chemical name O2, oxygen may be referred to as GOX or GO when produced and delivered in gaseous form, or as LOX or LO when in its cryogenic liquid form.

Oxygen is produced in large quantities and at high purity as a gas or liquid by cryogenic distillation and as a lower purity gas (typically about 93%) by adsorption technologies (pressure swing adsorption, abbreviated as PSA, or vacuum-pressure swing adsorption, abbreviated as VPSA or more simply, VSA).

Oxygen is valued for its reactivity. Oxygen is commonly used, with or instead of air, to increase the amount of oxygen available for combustion or biological activity. This increases reaction rates and leads to greater throughput in existing equipment and smaller sizes for new equipment.

Oxygen has numerous uses in steelmaking and other metals refining and fabrication processes, in chemicals, pharmaceuticals, petroleum processing, glass and ceramic manufacture, and pulp and paper manufacture. It is used for environmental protection in municipal and industrial effluent treatment plants and facilities. Oxygen has numerous uses in healthcare, both in hospitals, outpatient treatment centers and home use. For some uses, such as effluent treatment and pulp and paper bleaching, oxygen is converted to ozone (O3), an even more reactive form, to enhance the rate of reaction and to ensure the fullest possible oxidation of undesired compounds.

Oxygen is used with fuel gases in gas welding, gas cutting, oxygen scarfing, flame cleaning, flame hardening, and flame straightening. In gas cutting, the oxygen must be of high quality to ensure a high cutting speed and a clean cut.

The largest user of oxygen is the steel industry. Modern steelmaking relies heavily on the use of oxygen to enrich air and increase combustion temperatures in blast furnaces and open hearth furnaces as well as to replace coke with other combustible materials. During the steel making process, unwanted carbon combines with oxygen to form carbon oxides, which leave as gases. Oxygen is fed into the steel bath through a special lance. Oxygen is used to allow greater use of scrap metal in electric arc furnaces. Large quantities of oxygen are also used to make other metals, such as copper, lead, and zinc.

Oxygen enrichment of combustion air, or oxygen injection through lances, is used to an increasing extent in cupola furnaces, open-hearth furnaces, smelters for glass and mineral wool, and lime and cement kilns, to enhance their capacity and reduce energy requirements. Smelting times and energy consumption can also be reduced by special oxy-oil or oxy-gas burners in electro-steel furnaces and induction smelters for aluminum. A high thermal efficiency is achieved by these “oxy-fuel” burners, which mix fuel and oxygen at the tip of the burner. As a result, rapid combustion occurs at approximately 2800o C (5072°F).

Oxygen is used as a raw material in many oxidation processes, including the manufacture of ethylene oxide, propylene oxide, synthesis gas using partial oxidation of a wide range of hydrocarbons, ethylene dichloride, hydrogen peroxide, nitric acid, vinyl chloride and phthalic acid. Very large quantities of oxygen are used in coal gasification — to generate a synthesis gas that can be used as a chemical feedstock or precursor for more easily- transported and easily-used fuels.

Oxygen is used to enrich the air feed to catalytic cracking regenerators, which increases capacity of the units. It is used in sulfur recovery units to achieve similar benefits. Oxygen is also used to regenerate catalysts in refineries. Oxygen is used to achieve more complete combustion and destruction of hazardous and waste materials in incinerators.

Conversion of combustion systems from air-fuel to oxy-fuel (and construction of new furnaces and tanks around this technology) results in better control of heating patterns, higher furnace efficiencies (lower fuel consumption) and reduction in particulate and NOx emissions.

Oxygen is increasingly important as a bleaching chemical. In the manufacture of high-quality bleached pulp, the lignin in the pulp must be removed in a bleaching process. Chlorine has been used for this purpose but new processes using oxygen reduce water pollution. Oxygen plus caustic soda can replace hypochlorite and chlorine dioxide in the bleaching process, resulting in lower costs. In a chemical pulp mill, oxygen added to the combustion air increases the production capacity of the soda recovery boiler and the lime-reburning kiln. The use of oxygen in black liquor oxidation reduces the discharge of sulfur pollutants into the atmosphere.

In medicine, oxygen is used during surgery, intensive care treatment, inhalation therapy, etc. High standards of purity and handling must be maintained. Oxygen is typically supplied to hospitals though bulk liquid deliveries, then distributed to usage points. It assists with respiratory problems, saving lives and increasing patient comfort.

Small portable air separation units are gaining wide use in home care. Larger scale units using which also use non-cryogenic air separation technology, are being utilized in small and/or remote hospitals where demand is high enough to make cylinder deliveries a logistical problem but where liquid deliveries are unavailable or very costly. These units typically producing 90 to 93% purity oxygen, which is adequate for most medical uses.

In the biological treatment of waste-water, the use of oxygen instead of air permits increased capacity in existing treatment plants. Injecting oxygen into sewers reduces hydrogen sulfide formation, which results in reduced corrosion and odor. Ozone is used for drinking water treatment, in particular when alternatives, such as chlorine, are undesirable.

Oxygen has many uses in breathing apparatus, such as those for underwater work and refinery and chemical plant self contained breathing apparatus. Aquaculture, the cultivation of fish in ponds uses oxygenated water to allow ensure sufficient oxygen is always present and to allow more fish to be raised or kept in a given size of pond or tank. Liquid oxygen is used in liquid-fueled rockets as the oxidizer for fuels such as hydrogen and liquid methane.

Ultra-high purity nitrogen generators are fully automatic systems that can produce up to 1100 cc/min of 99.9995% pure nitrogen for laboratory use. The generators are used for evaporating solvents, switching valves, purging chambers, and many other applications where a high-purity inert gas supply is required. Continuum nitrogen generators are ideal for providing carrier gas to gas chromatograph columns. They are also well-suited for use with packed column instruments.

Produces a continuous supply of 99.9995% ultra-high purity nitrogen gas from existing compressed air. Output purity exceeds UHP cylinder gas specifications at a fraction of the cost.

Eliminates the need for costly, dangerous, inconvenient nitrogen cylinders in the laboratory.

Compact design frees-up valuable floor space.

Offers long-term cost stability --- uncontrollable vender price increases, contract negotiations, long-term commitments and tank rentals are no longer a concern.

Ideal for carrier gas applications.

Pays for itself in one to two years.

Install it once --- uses compressed air and one 120 VAC/60 Hz outlet.

Safe, reliable and low maintenance.

| MAXIMUM IMPURITIES (in ppm) | |

| Oxygen | 2 |

| Moisture | 2 |

| Argon | 3 |

| Carbon Dioxide + Carbon Monoxide | 1 |

| THC | 0.2 |

| Purity | 99.9992% |

Oxygen was known to be the only element that supports respiration as early as 1800 and was first used in the medical field in 1810. However, it took about 150 years for the gas to be used throughout medicine. In the early to mid 20th century oxygen therapy became rational and scientific, and today modern medicine could not be practiced without the support that oxygen supplies.

Most living things need oxygen to survive and oxygen's importance in the field of healthcare cannot be underestimated.Oxygen is widely used in every healthcare setting, with applications from resuscitation to inhalation therapy.

Oxygen is widely used in emergency medicine, both in hospital and by emergency medical services or advanced first aiders

high flow oxygen is definitively indicated for use in resuscitation, major trauma, anaphylaxis, major haemorrhage,

shock, active convulsions and hypothermia

provide a basis for virtually all modern anaesthetic techniques

restore tissue oxygen tension by improving oxygen availability in a wide range of conditions such as COPD, cyanosis, shock, severe hemorrhage, carbon monoxide poisoning, major trauma, cardiac/respiratory arrest

aid resuscitation

provide life support for artificially ventilated patients

reduce incidence of surgical wound infection

aid cardiovascular stability

used to treat victims of carbon monoxide poisoning

used to destroy bacteria

There are no absolute contraindications to the use of oxygen but the inspired concentration should be limited in the case of premature infants and those patients with chronic bronchitis and emphysema. However guidelines have been published by the British Thoracic Society (BTS) on the safe therapeutic use of medical oxygen, which encourages proper assessment of the patient before use. Compressed medical oxygen toxicity may manifest itself in the following ways

retrolenticular fibroplasia in premature infants exposed to oxygen concentrations greater than 40%

convulsions appear after a few hours exposure to medical oxygen at pressures above 3bar(g)

retrosternal soreness associated with coughing and breathing difficulties, made worse by smoking and exposure to cold air after breathing pure medical oxygen at atmospheric pressure for several hours

Oxygen is the second-largest volume industrial gas. Aside from its chemical name O2, oxygen may be referred to as GOX or GO when produced and delivered in gaseous form, or as LOX or LO when in its cryogenic liquid form. Oxygen is produced in large quantities and at high purity as a gas or liquid by cryogenic distillation and as a lower purity gas (typically about 93%) by technologies (pressure swing adsorption, abbreviated as PSA, or vacuum-pressure swing adsorption, abbreviated as VPSA or more simply, VSA).

Oxygen is valued for its reactivity. Oxygen is commonly used, with or instead of air, to increase the amount of oxygen available for combustion or biological activity. This increases reaction rates and leads to greater throughput in existing equipment and smaller sizes for new equipment.

Oxygen has numerous uses in steelmaking and other metals refining and fabrication processes, in chemicals, pharmaceuticals, petroleum processing, glass and ceramic manufacture, and pulp and paper manufacture. It is used for environmental protection in municipal and industrial effluent treatment plants and facilities. Oxygen has numerous uses in healthcare, both in hospitals, outpatient treatment centers and home use. For some uses, such as effluent treatment and pulp and paper bleaching, oxygen is converted to ozone (O3), an even more reactive form, to enhance the rate of reaction and to ensure the fullest possible oxidation of undesired compounds.

The largest user of oxygen is the steel industry. Modern steelmaking relies heavily on the use of oxygen to enrich air and increase combustion temperatures in blast furnaces and open hearth furnaces as well as to replace coke with other combustible materials. During the steel making process, unwanted carbon combines with oxygen to form carbon oxides, which leave as gases. Oxygen is fed into the steel bath through a special lance. Oxygen is used to allow greater use of scrap metal in electric arc furnaces. Large quantities of oxygen are also used to make other metals, such as copper, lead, and zinc.

Oxygen is used with fuel gases in gas welding, gas cutting, oxygen scarfing, flame cleaning, flame hardening, and flame straightening. In gas cutting, the oxygen must be of high quality to ensure a high cutting speed and a clean cut.

In the biological treatment of waste-water, the use of oxygen instead of air permits increased capacity in existing treatment plants. Injecting oxygen into sewers reduces hydrogen sulfide formation, which results in reduced corrosion and odor. Ozone is used for drinking water treatment, in particular when alternatives, such as chlorine, are undesirable.

Oxygen has many uses in breathing apparatus, such as those for underwater work and refinery and chemical plant self contained breathing apparatus.

Aquaculture, the cultivation of fish in ponds uses oxygenated water to allow ensure sufficient oxygen is always present and to allow more fish to be raised or kept in a given size of pond or tank.

Liquid oxygen is used in liquid-fueled rockets as the oxidizer for fuels such as hydrogen and liquid methane.

We provide argon uhp grade, grade i, commercial grade. We also provide pre-mix argon co2 mixture, argon oxyen mixture and other customised gas mixtures as per requirement. Our cylinders mandatorily have safety valve guards & hydro-test rings to ensure safety at all times.

Aluminum : To replace air or nitrogen, creating an inert atmosphere conducive to manufacturing aluminum; to assist in the removal of unwanted soluble gases during degasification; and to remove dissolved hydrogen and particulates from molten aluminum.

Electronics : To provide a protective atmosphere and heat-transfer medium for growing germanium and silicon crystals for ultra-pure semiconductors.

Glass : Because of its low thermal conductivity, argon provides window manufacturers with the gas barrier they need to produce double-pane insulated windows. During the production process, argon gas is injected between two window panes. This insulation barrier greatly improves the window's energy efficiency.

Lighting : To fill incandescent and fluorescent light bulbs; to create a blue light in neon-type lamps.

Metal Fabrication : To create an inert gas shield during welding; to provide an oxygen- and nitrogen- free environment for annealing and rolling metals and alloys; and to flush molten metals to eliminate porosity in castings.

Steel : To displace gas or vapors and prevent oxidation during processing; to obtain temperature consistency and homogenous composition by stirring molten steel; to assist in the removal of unwanted soluble gases during degasification; as a carrier gas, to determine the composition of a sample through gas chromatography; and to flush out carbon monoxide and reduce chromium losses in the Argon-Oxygen Decarburization (AOD) used during stainless steel refining.

Argon (Ar) is a noble gas that comprises 0.93 percent of the earth's atmosphere. (Noble gases are a group of rare gases that include argon, helium, krypton, neon, xenon and sometimes radon. They exhibit great stability and extremely low reaction rates. Also called inert gases.)

Colorless, odorless, tasteless and nontoxic, argon forms no known chemical compounds. A specific gravity of 1.38 makes argon 25 percent heavier than air. At atmospheric pressure, it becomes a liquid at -302°F (-186°C). Noncorrosive and non-flammable, argon also exhibits low thermal conductivity and slight solubility in water.

We are well known for supplying ultra high pure argon gas which is critical in carrying out applications in different industries. The gas is free from contamination and adulterations, making them suitable for instruments on which they are employed.

Supplied in 1.5.Cu.M./ 7 Cu.M. / 7.5 Cu.m. / 175 Cu.m. capacity cylinders

We also offer ultra high argon gas which is widely used by our esteemed clients for a variety of purposes. Our range of gas is known for its quality features like :-

- Purity

- Ability to withstand different conditions

- Accurate composition

- Effectiveness

Our team of quality experts make sure that these gases are filled in cylinders which are resistant to leak and tampering. Moreover, our logistics team ensures safe and timely delivery of the consignment to the client’s specified address. The cylinder capacity offered by us is 7 Cu.M.

Our range of quality assured ultra high pure argon gas is widely used in the industries for its inertness and capacity to sustain extreme conditions. We supply ultra high pure argon gas which is used in high temperature industrial processes, where other substances become highly reactive. Some of the applications of the product are mentioned below :-

- Used in graphite electric furnaces

- As an alternative to nitrogen and oxygen at very high temperatures

- Used in inert gas welding processes

- Processing of titanium and other reactive elements

- Argon atmosphere used for growing crystals of silicon and germanium

- 1.5. Cu.M

- 7 Cu.M

- 7.5 Cu.M

- 175 Cu.M

- Ethylene 2.8 means 99.8% purity

- Argon 6.0 means 99.9999% purity

| MAXIMUM IMPURITIES (in ppm) | |

| Oxygen | 1 |

| Moisture | 1 |

| Carbon Dioxide | Nil |

| Carbon Monoxide | Nil |

| Nitrogen | 0.5 |

| Hydrogen | Nil |

| THC | 0.5 |

| Methane | Nil |

| Total Impurities | 3 |

| Purity | 99.9997% |

Argon is produced industrially by the fractional distillation of liquid air. Argon is mostly used as an inert shielding gas in welding and other high-temperature industrial processes where ordinarily non-reactive substances become reactive; for example, an argon atomosphere is used in graphite electric furnaces to prevent the graphite from burning. Argon gas also has uses in incandescent and fluorescent lighting, and other types of gas discharge tubes. Argon makes a distinctive blue-green gas laser

- Size 80

- High Pressure Industrial Cylinder DOT Specification : 3AA -2015 - Canada 3AA-M154 O.D.: 7" - 178 mm

- Length: 31 - 787 mm

- Weight: 49 lbs - 22.2 kg

- Water Volume : 942

- Cubic Inches - 15.4 ltrs Airco/BOC = Q Praxair = Q Air Products = C Sizes may vary by location

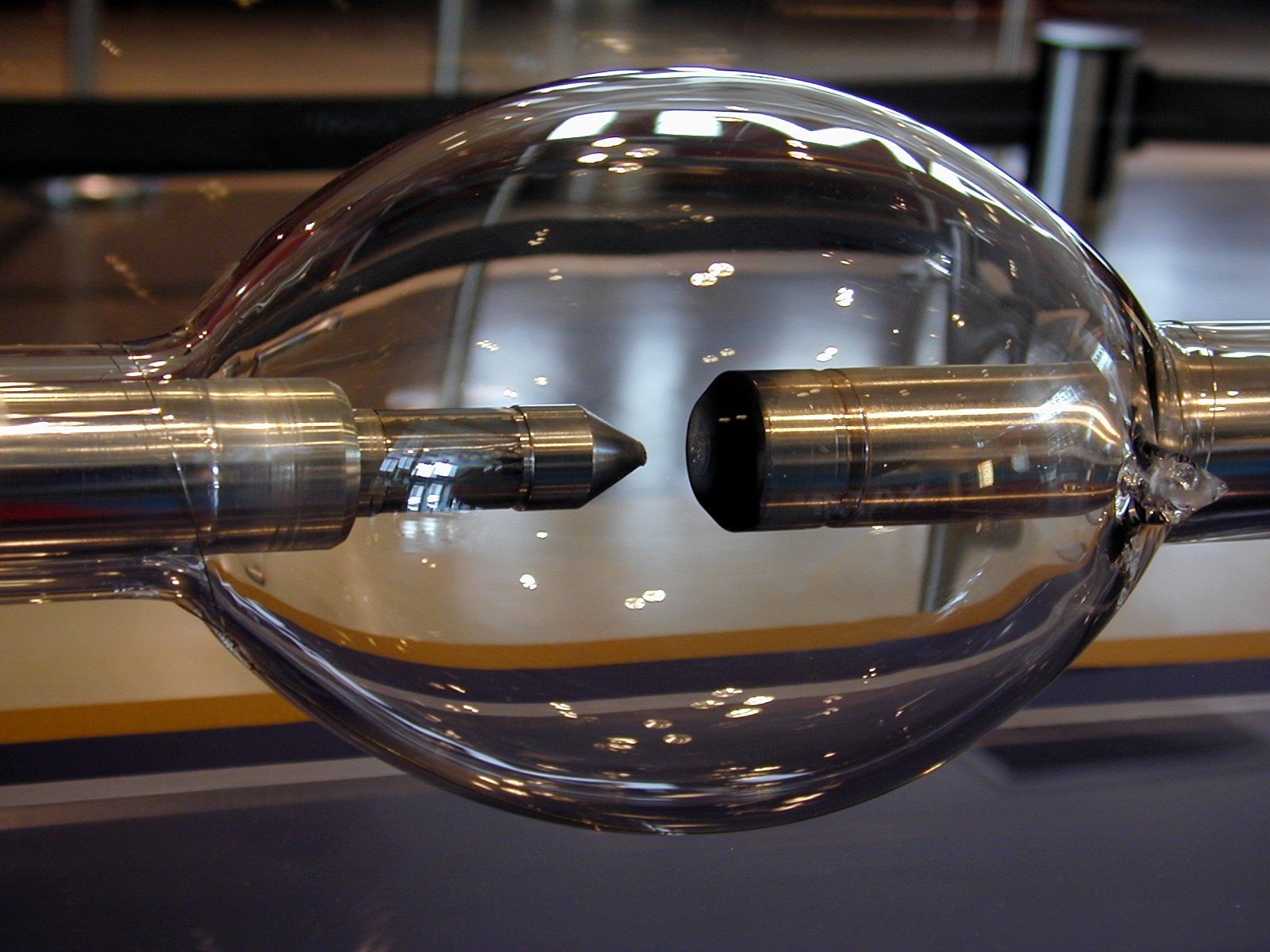

Student Grade, for demonstration onlyl.The classic demonstration of spectral lines. Each tube has its characteristic spectrum when energized before a spectroscope. Ideal for acquainting students with the spectra of better known gases in their pure form and for wavelength determination. The glass tubes are 25cm long with the capillary portion about 10cm long. An electrode is sealed in each end and attached to a metal end cap with a loop for convenient hookup to wire connections. Recommended for use with our Spectrum Tube Power Supply.

- Size 80

- High Pressure Industrial Cylinder DOT Specification : 3AA -2015 - Canada 3AA-M154 O.D.: 7" - 178 mm

- Length: 31 - 787 mm

- Weight: 49 lbs - 22.2 kg

- Water Volume : 942

- Cubic Inches - 15.4 ltrs Airco/BOC = Q Praxair = Q Air Products = C Sizes may vary by location

Argon (Ar) is a noble gas that comprises 0.93 percent of the earth's atmosphere. (Noble gases are a group of rare gases that include argon, helium, krypton, neon, xenon and sometimes radon. They exhibit great stability and extremely low reaction rates. Also called inert gases.

Colorless, odorless, tasteless and nontoxic, argon forms no known chemical compounds. A specific gravity of 1.38 makes argon 25 percent heavier than air. At atmospheric pressure, it becomes a liquid at -302° F (-186° C). Non corrosive and non-flammable, argon also exhibits low thermal conductivity and slight solubility in water.

A co-product of oxygen and nitrogen production, argon is manufactured commercially by means of air separation technology. In a cryogenic process, atmospheric air is compressed and cooled. Following liquefaction, the air is fractionally distilled based on the different boiling points of each component. (The boiling point of argon is between those of nitrogen and oxygen.)

During distillation, liquid nitrogen is the first product extracted from the high-pressure column. Next, a stream containing oxygen and argon (plus other gases) is withdrawn. The crude stream, containing approximately 10 percent argon, is refined in a separate distillation column to produce argon with 98 percent purity.

Manufacturers can further refine the stream by mixing the argon with hydrogen, catalytically burning the trace oxygen to water, drying and, finally, distilling the stream to remove remaining hydrogen and nitrogen. Using this process, producers can achieve an argon product with 99.9995 percent purity.

Argon-CO2 mixtures are slow gasses with low diffusion, and are therefore used sometimes for high precision chambers. These mixtures are free of hydrocarbons, and are therefore fairly safe with respect to ageing in high rate environments. Other Mixtures are as follows :-

- Ar + Co2

- 86 : 14 Mix

- 92 : 8 Mix

- Ar + N2

- 86 : 14 Mix

- 90 : 10 Mix

- Ar+He

- Inert Gas Shield In Are Welding

- A.O.D. Process For Manufacturing Stainless Steel

- Refining Of Copper & Stainless Steel

- Excimer Laser with Helium or Neon

- Carrier Gas in Gas Chromatography & Gas Analysis

- Filling of Lamps with Nitrogen/Non/Krypton & Valve manufacture

- Brazing & Soldering In Metal Refining

- Geiger Counting Tubes

- Inductive Coupled Plasma

- Vacuum Spectrometry

- Shielding Atmosphere for Flushing Molten METALS to Eliminate Porosity

- In Degassing Of Ferrous and Non – Ferrous Alloys

- Aircraft & Missile Industries

- Heat Treatment of Reactive Metals and Alloys

Gaseous chemical element, symbol: He, atomic number: 2 and atomic weight 4,0026 g/mol. Helium is one of the noble gases of group O in the periodic table. It’s the second lightest element. The main helium source in the world is a series of fields of natural gas in the United States.

Helium is an extremely versatile gas due to its favourable physical and chemical properties, such as low density, small atom radius, high thermal conductivity and low boiling point.

Helium is a colorless, odorless, insipid and non-toxic gas. It’s less soluble in water than any other gas. It’s the less reactive element and doesn’t essentially form chemical compounds. The density and viscosity of helium vapour are very low. The termic conductivity and the caloric content are exceptionally high. Helium can be liquefied, but its condensation temperature is the lowest among all the known substances.

Helium has many unique properties: low boiling point, low density, low solubility, high thermal conductivity and inertness, so it is use for any application which can exploit these properties. Helium was the first gas used for filling balloons and dirigibles. This application goes on in altitude research and for meteorological balloons. The main use of helium is as an inert protection gas in autogenous welding. Its biggest potential is found in applications at very low temperatures. Helium is the only cooler which is capable of reaching temperatures lower than 15 K (-434ºF). The main application of ultra low temperature is in the development of the superconductivity state, in which the resistance to the electricity flux is almost zero. Other applications are its use as pressurizing gas in liquid propellants for rockets, in helium-oxygen mixtures for divers, as working fluid in nuclear reactors cooled down by gas and as gas carrier in chemical analysis by gas chromatography.

- Color Middle Brown

- Chemical Name He

- Indian Standard IS

- Water Capacity 47 Liter

- Contents 7 Cubic Meter Gas

- Require Pressure 140–150 Kg.(Variation±5Kg/cm2)

- Molecular Weight 4.003 kg/kmol

- Critical Temperature -268.0°C

- Critical Pressure 2.2 bar

- Boiling point at 1.013 bar -268.9°C

- Gas density at 1.013 bar 0.169 kg/m3

- Relative gas density to air = 1 0.138

- Compressibility at 1.013 bar 1.00

- Helium Total Purity By Volume (%) Maximum Levels Of Impurities (ppm by volume)

- Grade Code O2 H2O N2 Ar CO + CO2 H2 THC Nitrogen Oxides

- Helium - Speical He - SPL 99.9985 2.0 2.0 10.0 Nil 0.5 Nil 0.5 Nil

- Helium - Standard He - STD 99.995 4.0 4.0 40.0 0.5 1.0

Hydrogen, or H2, is the lightest of all gases. Commonly found in nature in compounds with other elements, it is the most abundant element in the universe.

Hydrogen is a component of water, minerals and acids, as well as an essential part of all hydrocarbons and essentially all other organic substances. In fact, 98 percent of the known universe - most notably the sun and stars - consists of hydrogen.

Colorless, odorless, tasteless and nontoxic, hydrogen exists as a gas at atmospheric temperatures and pressures. A stable molecule because of its high bond strength, hydrogen becomes reactive at elevated temperatures or with the aid of catalysts. When cooled to its boiling point of -423°F (-253°C), hydrogen becomes a liquid that is approximately 93 percent lighter than water. All other gases - except helium - become solids at this temperature. Hydrogen is flammable and burns in air with a pale blue, almost invisible flame. In its gaseous form, hydrogen dissipates quickly. These unique properties call for strict safety measures in hydrogen use and storage.

| CHEMICAL PARAMETER | PRODUCT SPECIFICATION | UNIT |

| Hydrogen, UHP | 99.999 | % |

| Oxygen | 1 | ppmv |

| Nitrogen | 4 | ppmv |

| Carbon Monoxide | 0.5 | ppmv |

| Carbon Dioxide | 0.5 | ppmv |

| THC | 0.5 | ppmv |

| Moisture | 1 | ppmv |

- Odourless, colourless and tasteless

- Will ignite easily so cylinders must not be snifted

- Burns with an invisible flame

- Produces a flame of approximately 2834°C when used with oxygen

- Supplied in high-pressure cylinders

- Has the highest thermal conductivity of all gases

- Is supplied at higher pressures than other fuel gases

- Burns with a clean carbon-free and soot-free flame

- An important addition to argon in a range of argon-hydrogen shielding gases for TIG and plasma welding

- Shielding gas mixtures are primarily used for welding austenitic stainless steels and some nickel alloys

- Can be used with argon in a range of gas mixtures for plasma-cutting primarily stainless steel and aluminium

- Used with oxygen for underwater flame-cutting. Deeper cutting requires increased pressure of fuel and oxygen

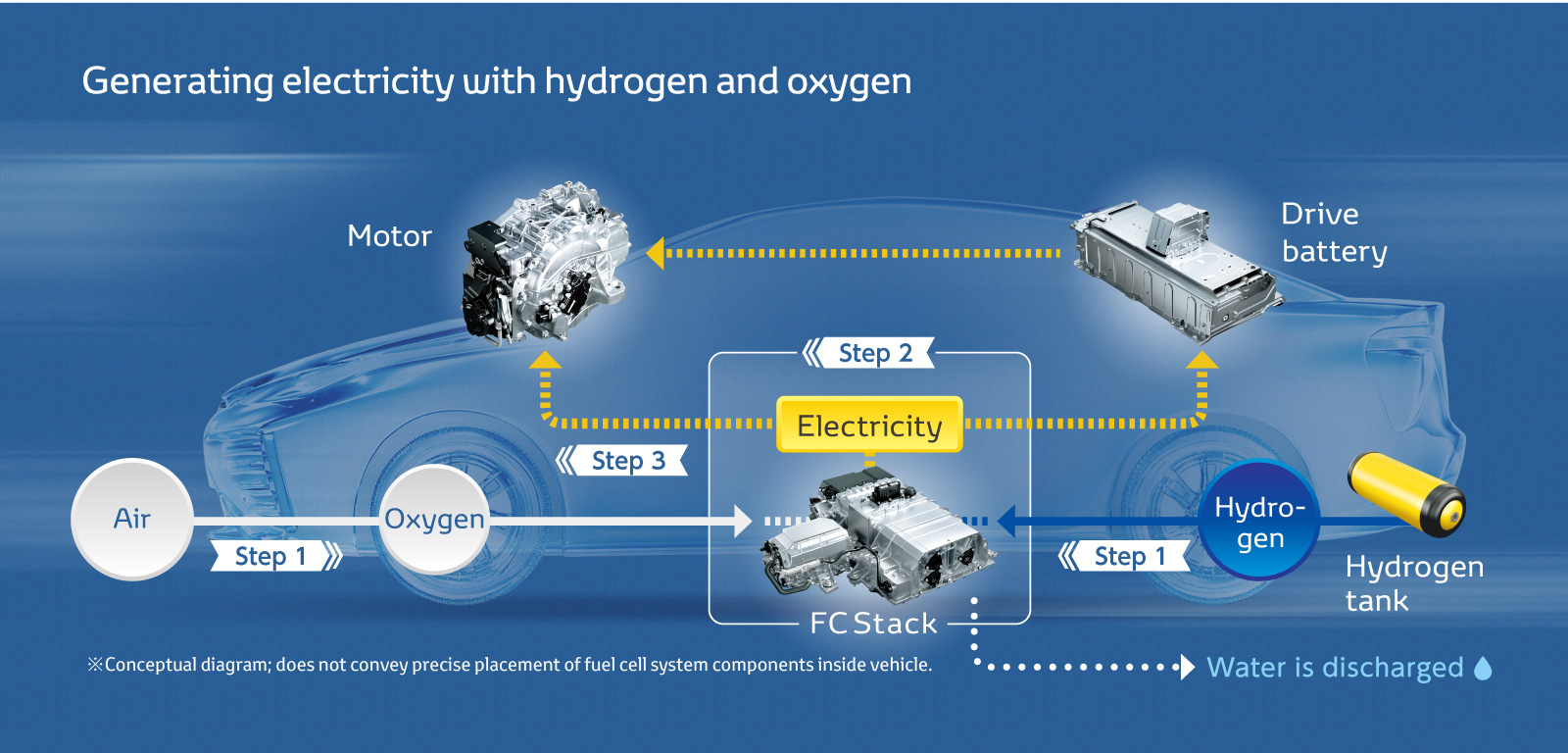

- Can be used as an alternative power source when used with a fuel cell to generate electricity

- In the glass industry, used to form the rim on glasses

Carbon dioxide is one of the most abundant gasses in the atmosphere. Carbon dioxide plays an important part in vital plant and animal process, such as photosynthesis and respiration. These processes will be briefly explained here.

Green plants convert carbon dioxide and water into food compounds, such as glucose, and oxygen. This process is called photosynthesis.

The reaction of photosynthesis is as follows :

6CO2 + 6H2O --> C6H12O6 + 6O2

Plants and animals, in turn, convert the food compounds by combining it with oxygen to release energy for growth and other life activities. This is the respiration process, the reverse of photosynthesis.

The respiration reaction is as follows :

C6H12O6 + 6O2 --> 6CO2 + 6H2O

- A colourless and odourless gas that can cause the nose to sting in high concentrations

- Toxic in high concentrations

- An asphyxiant (does not support life)

- Slightly corrosive in the presence of moisture

- Heavier than air, carbon dioxide will collect in ducts, drains and low-lying areas

- Highly soluble in water at moderate temperatures

- At elevated temperatures, carbon dioxide reacts with many substances

- Cylinders of both liquid and gaseous carbon dioxide are available from BOC. Dip tubes are used in liquid withdrawal carbon dioxide cylinders to extract the liquid from the cylinder. The tube runs down the centre of the pressurised cylinder and draws the liquid up through the valve. To identify these cylinders, a white stripe is painted down the length of the cylinder

- Higher density than air provides good blanketing properties

- This chemical property has led to its use as a reactant in some chemical processes

- A range of electrical vaporisers which can be used for increasing flow rates

- MIG-welding mild steel

- For welding carbon and alloy steel and stainless steel with flux-cored wires

- Shielding gas in plasma-cutting

- Liquid for substrate cooling to control the heat build-up when thermal and plasma-spraying

- Use of the Argoshield range as the preferred mild steel MIG-welding gas

- Suitable for inerting applications

- Balancing pH levels in swimming pools

- Compressed liquid carbon dioxide can also be used in small pipe-freezing applications

- Dry carbon dioxide is non-corrosive; hence common materials are acceptable, e.g. steel, iron, copper, brass and plastic. Moist carbon dioxide is slightly corrosive so suck back of moisture from the atmosphere through an open valve of an empty cylinder must be avoided by closing the valve after use.

- A carbon dioxide regulator cannot be used with any other gas cylinder due to the different fittings and pressure levels.

The composition of the mixtures available is practically infinite. It is restricted only by the physical and chemical properties, health, safety norms and the Stability and quality of the final mixture. At CSL we offer our clients any desired preparation tolerance and certification accuracy depending on the mixture components. We prepare mixture using highly accurate gravimetric / volumetric techniques traceable toNational Physical Laboratory standard masses. We have advanced imported computerized gas chromatograph system which enables higher accuracy and precision for each gas mixture.

Environmental and Pollution Control Gases : CL2, SO2, CO, NO, NO2, H2S, HCL, NH3 gases are available in PPM and % range, flue gas measurement, synthetic air and zero air.

Medical Application : Respiratory gas, incubation bio chemistry, sterilizing medical equipment. Blood gas analyzer, lung function analysis, 35 ppm, NO bal NO2 mixture. Pulmonary function test mixture.

Laser Application :- Gas mixture for CO2 lasers and marking lasers.

Lighting : To fill incandescent and fluorescent light bulbs; to create a blue light in neon-type lamps.

Automotive Application : Gases for exhaust Gases.

Semiconductor Application : Silane Gas mixture.

Steel Industry Application : Reduction Gases for metallurgy, CO2, CO, O2, H2, Air and N2.

Food Packaging Application : N2, CO2 and O2 Gas Mixture.

| Component | Concentration | Balance |

| Ammonia | 10-500 ppm | Air or Nitrogen |

| Chlorine | 2-1000 ppm | Nitrogen |

| Carbon Monoxide | 10-2000 ppm | Air or Nitrogen |

| Ethylene Oxide | 5-100 ppm | Nitrogen |

| Hydrogen Cyanide | 5-20 ppm | Nitrogen |

| Hydrogen Chlorine | 3-1000 ppm | Nitrogen |

| Hydrogen Sulfide | 5 ppm – 1% vol. | Air or Nitrogen |

| Nitric Oxide | 5-900 ppm | Nitrogen |

| Nitrogen Dioxide | 3-200 ppm | Air or Nitrogen |

| Phosphine | 0.5-15 ppm | Nitrogen |

| Silane | 5-10 ppm | Nitrogen |

| Sulfur Dioxide | 2-100 ppm | Air or Nitrogen |

| Component | Concentration | Balance |

| Benzene | 1-5 ppm | Air |

| Butane | 10 ppm – 0.9% vol. | Air |

| Carbon Dioxide | 50 ppm – 100% vol. | Air or Nitrogen |

| Ethylene | 10 ppm – 1.35% vol. | Air |

| Helium | 100% vol. | N/A |

| Hexane | 10 ppm – 0.48% vol. | Air |

| Hydrogen | 10 ppm – 2.0% vol. | Air or Nitrogen |

| Isobutylene | 10 ppm – 100 ppm | Air |

| Methane | 10 ppm – 2.5% vol. | Air or Nitrogen |

| Methyl Chloride | 10 ppm – 300 ppm | Air |

| Methylene Chloride | 10 ppm – 200 ppm | Air |

| Oxygen | 0.4% - 100% vol. | Nitrogen |

| Pentane | 10 ppm – 0.75% vol. | Air |

| Propane | 10 ppm – 1.1% vol. | Air |

| Propylene | 50 ppm – 5.6% vol. | Nitrogen |

| Toluene | 10 ppm – 100 ppm | Air or Nitrogen |

| Zero Air | 20.9% Oxygen | Nitrogen |

| Nitrogen | 100% vol. | N/A |

- the hottest and most efficient of all the fuel gases, providing high levels of productivity

- very efficient use of oxygen

- lighter than air and will not accumulate at low levels

- low ignition energy

- low moisture content flame

- non-toxic (may cause dizziness in high concentrations)

- Oxygen and acetylene together produce a flame temperature of approximately 3150°C

- The oxy-acetylene flame gives very good localised heating with a minimum of wasted heat

- In cutting, oxy-acetylene gives the fastest preheating and piercing times of any fuel gas combination

- In oxy-acetylene cutting processes, improved cut quality, higher cutting speed, faster cut initiation time and reduced oxygen use are achieved

- When used with either oxygen or air, acetylene can produce a thin layer of black carbon particles. This can prevent components sticking in their moulds

- Unused gas will not collect in low-lying areas, ducts and drains causing a potential hazard

- Acetylene is stored in specially-designed cylinders to prevent decomposition

- The flame has a low moisture content making it a good choice for many critical heating applications

- Cutting

- Flame heating

- Flame gouging

- Gas welding. The only fuel gas which can be used to weld steel Flame hardening. An oxy-acetylene flame can be used where the hardened surface of carbon steel components is either in situ as a remedial process or on components too large to fit in a furnace

- Flame cleaning. A wide oxy-acetylene flame is held very close to a steel surface to be cleaned

- Flame straightening where the precise and efficient flame properties are used to remove distortion in plate material

- Thermal spraying of various metals and ceramics. The material to be sprayed is fed through the flame

- Spot-heating applications

- Brazing

- Texturing

- Profile-cutting

- Branding wooden pallets

- Wood-ageing

- Glass and metal castings

- Mould release and other anti-stick applications

- The only fuel gas recommended for use in underground working conditions

- Care must be taken when using acetylene as it is an asphyxiant

- Acetylene is highly reactive. It is dissolved in acetone and contained within a porous mass inside the cylinder

- Acetylene can react over time with some metals to form explosive acetylides

- Acetylene is slightly lighter than air and will collect at ceiling level

Nitrous oxide (chemical compound N2O) is a non-flammable, colourless gas with a slightly sweet odour. It is a dissociative drug which was discovered in 1772 and has been in common usage recreationally since the early 1800s.

The psychological effects of nitrous oxide were discovered in 1799 by British chemist and inventor Humphry Davy. When inhaled, nitrous oxide can cause euphoria, sedation, analgesia (pain relief), laughter/giggling, dissociation of the mind from the body, auditive distortions, visual hallucinations (rare) and other phenomena. In 1800, Humphrey Davy started marketing nitrous oxide as a recreational drug. Nitrous oxide was called ‘laughing gas’ and its use became popular at social events, predominantly those of the British upper classes, where it was commonly sold for entertainment. In modern times, nitrous oxide is sometimes used at parties, usually filled into balloons and inhaled from them.

As it's primary medical use is sedative and analgesic, nitrous oxide is used as an anaesthetic in dentistry and sometimes in surgery. Nitrous oxide is also used in the dairy industry, in car racing, in welding and in rocket engines.

- Nitrous oxide works very rapidly – it reaches the brain within 20 seconds, and relaxation and pain-killing properties develop after 2 or 3 minutes.

- The depth of sedation can be altered from moment to moment, allowing the person who administers the gas to increase or decrease the depth of sedation. Other sedation techniques don't allow for this. For example, with IV sedation, it's easy to deepen the level of sedation, but difficult to lessen it. Whereas with laughing gas, the effects are almost instant.

- Other sedation techniques have a fixed duration of action (because the effects of pills or intravenous drugs last for a specific time span), whereas gas can be given for the exact time span it's needed for. It can also be switched off when not needed and then switched on again (though to avoid a roller-coaster effect, you shouldn't do this too abruptly).

- There's no "hangover" effect – the gas is eliminated from the body within 3 to 5 minutes after the gas supply is stopped. You can safely drive home and don't need an escort.

- With nitrous oxide, it's easy to give incremental doses until the desired action is obtained (this is called "titration"). So the administrator has virtually absolute control over the action of the drug, preventing the possibility of accidental overdoses. While giving incremental doses is possible with IV sedation, it's not possible with oral sedation (as a result, oral sedation can be a bit of a hit-and-miss affair).

- For certain procedures – those involving gums rather than teeth (e. g. deep cleaning) – it may be possible to use nitrous instead of local anaesthesia. N2O acts as a painkiller on soft tissues such as gums. However, its pain-relieving effects vary a lot from person to person and can't be relied upon.

- No injection is required. In cases of very severe needle phobia, getting laughing gas first can help you feel relaxed enough to allow the needle required for IV sedation to be inserted in your arm or hand. The very deep state of sedation achievable through IV sedation will then allow you to accept local anaesthetic.

- Inhalation sedation is very safe. It has very few side effects and the drugs used have no ill effects on the heart, lungs, liver, kidneys, or brain.

- Inhalation sedation has been found to be very effective in eliminating or at least minimizing severe gagging.

- Some people are not comfortable with the effects of laughing gas (either because they're afraid they might lose control or because it makes them feel nauseous – this is quite rare, though, and usually due to oversedation). If you're prone to nausea, it's a good idea to have a meal (not a huge one) about 4 hours before your appointment. If that's not possible (e. g. an early morning appointment), make sure your stomach isn't completely empty – but don't stuff yourself straight beforehand either.

- Some people will not achieve adequate sedation with permissible levels of oxygen.

- f you can't breathe through your nose (either because you're a pure mouth breather, or because your nose is blocked), or you feel too claustrophobic when something is put over your nose, it can't be used.

- Depending on where you live, a dentist who offers nitrous oxide may be hard to come by.

- Apart from that, most of the disadvantages of inhalation sedation don't affect you, but the dental team: there's training required, the equipment is quite bulky and takes up a lot of space, and there is a possibility that dental staff who are chronically exposed to nitrous oxide might develop health problems. The cost of the equipment and gases is high, so you'll have to contribute to the cost – but it's quite a bit cheaper than IV sedation.

| Purity | 98.0% V / V (Min) |

| Carbon Monoxide | 10 ppm V / V (Max) |

| Carbon Dioxide | 300 ppm V / V (Max) |

| Acidity / Alkalinity | Passes Limit Test |

| Arsine & Phosphine | Nil |

| Halogens & Hydrogen Sulphide | Nil |

| Nitric Oxide & Nitrogen Dioxide (NO / NO2) | 2 ppm V / V (Max) |

| Oxidising Substances | Nil |

| Moisture | 2.0 mg / litre (Max) |

- Care must be taken when using acetylene as it is an asphyxiant

- Acetylene is highly reactive. It is dissolved in acetone and contained within a porous mass inside the cylinder

- Acetylene can react over time with some metals to form explosive acetylides

- Acetylene is slightly lighter than air and will collect at ceiling level

Compressed air is a gas, or a combination of gases, that has been put under greater pressure than the air in the general environment. Current applications using compressed air are numerous and diverse, including jackhammers, tire pumps, air rifles, and aerosol cheese. According to proponents, compressed air also has a great deal of potential as a clean, inexpensive, and infinitely renewable energy source. Its use is currently being explored as an alternative to fossil fuels.

In 1991, the first compressed air energy storage (CAES) plant in the United States opened in McIntosh, Alabama. The world's largest CAES plant, planned for Norton, Ohio, is expected to store sufficient energy to provide electric power for 675,000 homes for two days. Another product that uses compressed air is the so-called "air car" currently in development by several manufacturers, and expected to be on the market within the next few years. According to "How Stuff Works," one such car, the e.Volution, will run 120 miles without refueling, at a cost of about 30 cents.

Compressed air in spray cans (sometimes called canned air ) is often used to clean things that are especially delicate or sensitive, such as keyboards or the inside of computer cases.

- Odourless, colourless and non-toxic

- Does not burn but supports combustion

- When it is combined with a fuel gas, produces a flame with a lower temperature than an oxy-fuel flame

- The air-fuel flame is suitable for brazing and soldering applications with lower-temperature alloys

- Used in preference to oxygen because it gives a greater level of adjustment, allowing the thickness of the carbon coat to be varied

- Brazing and hard soldering

- Can be used in alternative applications such as plasma-cutting

- Used in metallurgical processes such as die-casting and blast furnaces

- Compressed air cylinders are an alternative to a compressor

- Used to drive pneumatic drills

- Can be used in the carbon-coating processes. An air-acetylene flame is used to produce carbon which can be deposited onto the surface of a component to act as a release agent. Carbon-coating is used for aluminium extrusion and glass manufacture as a mould-release agent

We also offer superior quality double cylinder trolleys sourced from well established manufacturers. These are equipped with retractable rear castors that provide better mobility as well as greater control over the trolley. Each trolley is tested and inspected to ensure higher efficiency both at manufacturer's end and at our premises. We offer these at best industrial prices.

-- Max SWL 80kg

-- Max Input Load 10kg

-- Max Cylinder Height 1500mm

-- Max Cylinder Diameter 450mm

-- Min Cylinder Diameter 300mm

-- Overall Width 460mm

-- Pneumatic Tyres on Rear Wheels

Aluminium Cylinders are the lightweight alternative to traditional steel equivalents,combining optimum weight savings with extender gas delivery and exceptional strength.

- High-performance

- Lightweight specifications

- Increased gas delivery

- Highly portable and easy to maneuver Exceptional Strength and durability

- Non-magnetic

- Excellent corrosion resistance

Light Weight & Portable : Made of aluminium, generally upto 50% lighter then the steel cylinders, hence this makes the cylinders portable and easy to handle in emergency situations.

Seamless & Corrosion Resistant : The cylinders are extremely strong with uniform properties and are high corrosion resistance. Even the smooth, inert surface prolongs the life of high purity gases and the cylinders does not even get contaminated.

Safety Standards & Quality : Highest quality of high strength aluminium alloy is used and each cylinder is tested at every stage of manufacturing. The quality and the safety conforms to the international standards.

Portacryo Vessels are used for Storing Liquids and Convert into gases for their uses instead of Cylinders.

-- No stocking of cylinders.

-- No movement and handling of cylinders.

Gas delivery at constant pressure.-- No requirement of high pressure regulators to reduce cylinder pressure.

-- Risk in storage of high pressure cylinders eliminated.

-- Loss of gas due to residual pressure of cylinders is eliminated.

-- Approximate stock capacity of 657 m3 of Nitrogen and 812 m3 of Oxygen which is equivalent to about 94 cylinders of Nitrogen and 116 cylinders of Oxygen.

-- High purity is ensured since the gas is in liquefied (Cryogenic) form and obtained directly from the air separation plant with manufacturers' test / quality certificate, wherever required.

-- Medium and Small Hospitals having either cryogenic liquid or gas application

-- Fabrication Workshops

-- Hospitals and Laboratories

-- Chemicals and Pharmaceuticals

-- Electronic Industries with high purity gas requirements

-- Remote purging

-- Automobile Industries

-- On-site Construction and Demolishing Units.

manufactures LIQUID OXYGEN, LIQUID NITROGEN, COMMERCIAL OXYGEN AND NITROGEN, HIGH PURE OXYGEN AND NITROGEN, ULTRA HIGH PURE NITROGEN,MEDICAL OXYGEN, INDUSTRIAL OXYGEN AND CARBON DIOXIDE.

Copyright © Sri Ram Balaji Gases 2016. All rights reserved.

Design & Developed by Webrivers